- Core Customization Service

- Gezondheidszorg

- Elektronische apparaten en instrumenten

- Mallen voor moeder- en kindbenodigdheden

- Recreatieve sporten

- Woninginrichting Kunst

- Auto-accessoires

- Transport en opslag

- Verlichtingsarmaturen

- Bouwapparatuur

- Verpakkingsproduct

- Educatief en laboratoria

- Kleding Bagage Accessoires

- Verzorgings- en reinigingsproducten

- Land- en bosbouw

- Mechanische uitrusting

- Dierbenodigdheden

- Keukengerei

China Buitenentertainment Fabrikant, leverancier, fabriek

Our indoor entertainment products molds include: Building Blocks.electronic game console.board game.billiards.Model assembly.Music equipment (karaoke).billiards.archery parts.MP3.CD player.Switch.

Mold for indoor entertainment products molds

With the improvement of people's living standards and the continuous increase in demand for indoor entertainment, the market's demand for indoor entertainment products continues to expand, thereby driving the development of injection mold manufacturers. Indoor entertainment products, as an important part of people's daily lives, have a growing demand in the injection mold market. Indoor entertainment product injection mold manufacturers not only need to meet the production needs of traditional products, but also need to respond to the market's demand for multifunctional products to adapt to the diversified needs of the market.

Ningbo (P&M) Plastic and Metal Products Co., Ltd. is a mold factory with over 10 years of experience in manufacturing indoor entertainment products. We can not only provide high-quality indoor entertainment products for retailers, but also customize innovative high-quality indoor entertainment products for well-known brands. Our company has a professional technical team and rich manufacturing experience, which can provide customers with high-quality mold products.Our advantage lies in having experienced mold masters who have extensive work experience in mold repair and processing, ensuring the quality and accuracy of molds. At the same time, the company also provides customers with efficient and high-quality pre-sales, in sales, and after-sales services, committed to creating first-class product and service quality.

The service we provide is one-stop. We can turn innovative products designed by our clients into reality. We will provide customers with professional production solutions based on their product design. We will design the most suitable mold for our customers based on the characteristics of the injection molding process. We address customer concerns from the source: 1. A good mold designer will ensure that the surface effect of the final product meets customer expectations. 2. Raw materials. We refuse to use recycled plastic raw materials, as our raw materials are traceable. Our food grade raw materials can undergo quality inspection. 3. Packaging. We have experienced workers, and every product is carefully packaged. 4. After sales service. We protect the rights and interests of our customers. We have a one-year warranty period and a one-on-one dedicated person in charge, allowing customers to place orders with confidence.

The manufacturing process and characteristics of our indoor entertainment products molds:

1. High precision and complex shapes

Injection molds are manufactured using advanced processing technology and precision equipment, capable of producing plastic products with high precision and accurate dimensions. Some indoor entertainment products such as building blocks require very high precision in size, and injection molds can meet these requirements to ensure that the size error of each product is controlled within a very small range. At the same time, injection molds can manufacture various complex shaped plastic products, and the cavity in the mold can be designed and processed according to the shape of the product, achieving complex geometric shapes and detail requirements. For example, some uniquely shaped indoor entertainment toys can only be efficiently produced through injection molding with their complex shapes.

2. Efficient Production and Economy

Injection molds can achieve efficient production. After the mold manufacturing is completed, continuous production of plastic products can be carried out through injection molding machines. Injection molding machines inject plastic at high speeds, allowing molds to produce large quantities of products in a short period of time and improving production efficiency. Although the manufacturing cost of molds is high, once completed, they can be used for a long time. A manufacturer of injection molds for indoor entertainment products, a set of high-quality injection molds can produce millions of products with low cost spread across each product. In addition, injection molds can be reused for large-scale production, reducing the manufacturing cost per unit product and improving economic efficiency.

3. Reliability and plasticity

Injection molds have high reliability. The mold is made of high-quality materials and undergoes precise processing and heat treatment to ensure its strength and hardness. During high-pressure injection molding, the mold is able to withstand impact and pressure, and is not easily deformed or worn, ensuring the quality and stability of the product. Meanwhile, injection molds have high plasticity and can be customized and modified according to customer needs to meet the production requirements of different products.

4. Maintainability

Injection molds can be repaired and maintained during use, extending their service life and reducing maintenance costs. When the mold is worn or damaged, cleaning, lubrication, and replacement of damaged parts can be carried out. We will regularly carry out maintenance work such as rust removal, re lubrication, and replacement of easily worn parts on the mold, which can effectively extend the service life of the mold. For indoor entertainment product injection mold manufacturers, good maintainability can reduce production costs and improve production efficiency.

5. Process steps

The manufacturing of injection molds can be roughly divided into the following steps:

Process analysis of plastic products: Before designing the mold, the mold designer needs to have a detailed understanding of the structure, dimensional accuracy, appearance requirements, etc. of indoor entertainment products, and evaluate whether the existing mold structure can achieve mass production.

Mold structure design: Mold designers design 3D engineering drawings, component drawings, parting drawings, assembly drawings, EDM drawings, electronic circuit diagrams, etc. based on the evaluation results. In the design process, it is necessary to fully consider the characteristics of indoor entertainment products, such as product shape, color, transparency requirements, as well as factors such as the performance of injection molding machines and the rationality of mold structures.

Determining mold materials and selecting standard components: When selecting mold materials, in addition to considering the accuracy and quality of the product, the actual processing and heat treatment capabilities of the mold factory should also be taken into account to make the correct choice. For injection molds for indoor entertainment products, suitable mold materials can be selected based on the product's usage environment and performance requirements, such as steel with high hardness and good wear resistance. At the same time, in order to shorten the manufacturing cycle, existing standard parts should be utilized as much as possible.

Part processing and mold assembly: In addition to the structure and reasonable tolerance fit provided during design, the accuracy of the mold is crucial for part processing and mold assembly. For injection molds for indoor entertainment products, high precision machining is required for key parts such as the mold cavity and core. High precision machining equipment is needed to ensure the dimensional accuracy and surface quality of the product. During the mold assembly process, attention should be paid to the precision of the fit between each component to ensure the sealing and stability of the mold.

Trial mold: Trial mold is an indispensable step in checking whether the mold is qualified and selecting the molding process. For injection molds for indoor entertainment products, it is important to focus on factors such as product appearance quality, dimensional accuracy, and molding cycle during mold testing. Based on the test results, the mold should be adjusted and optimized to ensure that it meets production requirements.

indoor entertainment products molds Description

Mold base: No. 45 steel

Model: H13

Cavity: Customized

Runner: Hot runner

Injection System: Ejector pin with automatic mechanism

Delivery time:25 days

Part Material: V0-ABS/V2-ABS

- View as

Visserijen

Voor vissersvormen heeft Ningbo (P&M) Plastic Metal Products Co., Ltd. 18 jaar van schimmelproductietechnologie en 10 jaar exportervaring. Wij bieden professionele one-stop aangepaste schimmeldiensten en zijn een professionele plastic schimmelfabrikant. We kunnen spuitgieten, blaasvorming, afstervende en rotatiemolken gebruiken.

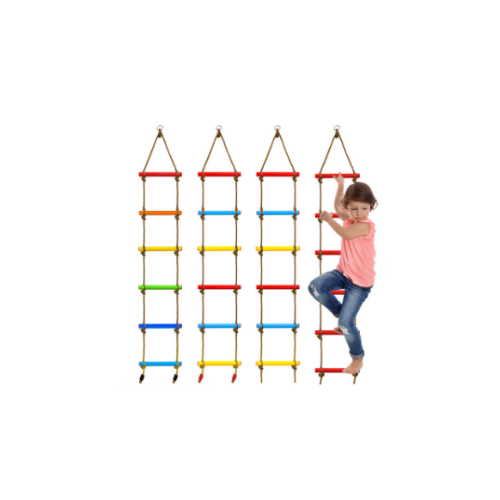

Lees verderStuur onderzoekSlijgieten van kinderen

Voor dia's van kinderen heeft Ningbo (P&M) Plastic Metal Products Co., Ltd. 18 jaar van schimmelproductietechnologie en 10 jaar exportervaring. Wij bieden professionele one-stop aangepaste schimmeldiensten en zijn een professionele plastic schimmelfabrikant. We kunnen spuitgieten, blaasvorming, afstervende en rotatiemolken gebruiken.

Lees verderStuur onderzoekWipkolte

Voor Seesaw Molds heeft Ningbo (P&M) Plastic Metal Products Co., Ltd. 18 jaar van schimmelproductietechnologie en 10 jaar exportervaring. Wij bieden professionele one-stop aangepaste schimmeldiensten en zijn een professionele plastic schimmelfabrikant. We kunnen spuitgieten, blaasvorming, afstervende en rotatiemolken gebruiken.

Lees verderStuur onderzoekKruipende frame -vorming

Voor kruipende framevormen heeft Ningbo (P&M) Plastic Metal Products Co., Ltd. 18 jaar van schimmelproductietechnologie en 10 jaar exportervaring. Wij bieden professionele one-stop aangepaste schimmeldiensten en zijn een professionele plastic schimmelfabrikant. We kunnen spuitgieten, blaasvorming, afstervende en rotatiemolken gebruiken.

Lees verderStuur onderzoekWaterspeelapparatuur gieten

Voor waterspeelapparatuur mallen heeft Ningbo (P&M) Plastic Metal Products Co., Ltd. 18 jaar van schimmelproductietechnologie en 10 jaar exportervaring. Wij bieden professionele one-stop aangepaste schimmeldiensten en zijn een professionele plastic schimmelfabrikant. We kunnen spuitgieten, blaasvorming, afstervende en rotatiemolken gebruiken.

Lees verderStuur onderzoekRotsklimmakgieten

Voor rotsklimmenstige mallvormen heeft Ningbo (P&M) Plastic Metal Products Co., Ltd. 18 jaar van schimmelproductietechnologie en 10 jaar exportervaring. Wij bieden professionele one-stop aangepaste schimmeldiensten en zijn een professionele plastic schimmelfabrikant. We kunnen spuitgieten, blaasvorming, afstervende en rotatiemolken gebruiken.

Lees verderStuur onderzoek